1. Harness binding design

The harness wrapping plays a role in wear resistance, flame retardancy, corrosion prevention, interference prevention, noise reduction and beautification of the appearance. Generally, the following wrapping design scheme is formulated according to the working environment and space size.

The engine harness has a bad working environment, so it is wrapped with threaded tubes with high flame retardancy, waterproof and high mechanical strength.

The working environment of the front cabin line is also relatively poor. Most branches are also wrapped with threaded pipes with good flame retardancy, and some branches are wrapped with PVC pipes.

The working space of the instrument line is small, and the environment is relatively good, which can be fully wrapped with tape or flower wrapped.

The working space of the door line and roof line is small, which can be fully wrapped with tape, and some branches can be wrapped with industrial plastic cloth; The thinner roof line can be directly pasted on the vehicle with sponge tape.

The chassis line has many contact parts with the vehicle body, so it is wrapped with corrugated pipes to prevent harness abrasion.

2. Performance Analysis of Raw Materials for Binding

| Material Science | Performance | Distribution position | Shortcoming |

| Threaded pipe | It has good wear resistance, high temperature resistance, flame retardancy, heat resistance and temperature resistance of - 40~150 ℃. It is generally made of PP and PA | Main part, high temperature area | PA has poor bending fatigue resistance; PP is less flame retardant and wear-resistant than PA |

| PVC tube | PVC pipe has good flexibility and bending deformation resistance, and is a closed pipe | At the branch where the harness turns | The heat resistance temperature of PVC pipe is not high, generally below 80 ℃ |

| Adhesive tape | PVC tape has good wear resistance and flame retardancy; The price is cheaper. The flannelette tape and cloth based tape are made of PET. The flannelette tape has the best binding property and noise reduction property, and the temperature resistance is above 105 ℃; The cloth based adhesive tape has the best abrasion resistance, and the temperature resistance can reach 150 ℃. | Binding, abrasion resistance, insulation, flame retardancy, noise reduction and marking | The temperature resistance of PVC tape is above 85 ℃, and the noise reduction is poor. The common disadvantage of flannelette tape and cloth based tape is poor flame resistance |

3. Wrap adhesive tape outside

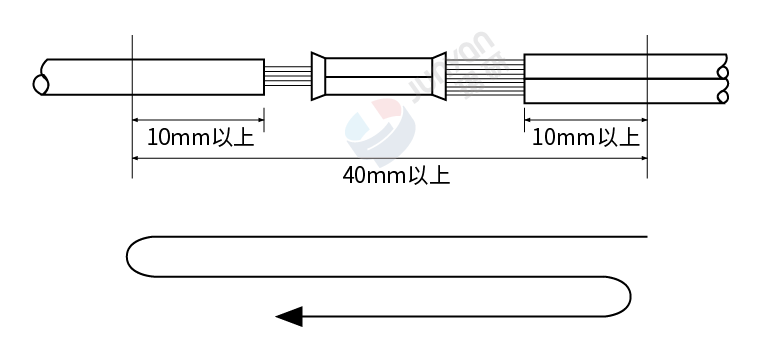

(1) Wrap some adhesive tape

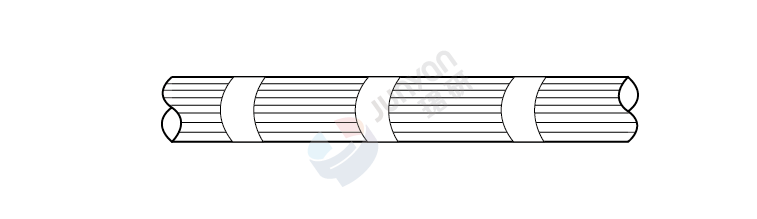

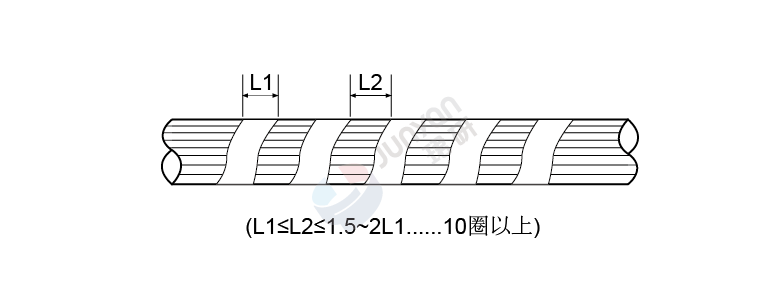

(2) Continuous tape wrapping at intervals

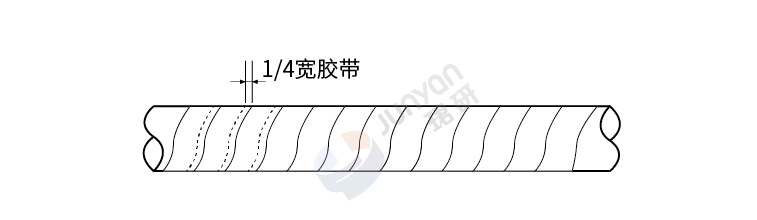

(3) Tightly wrapped adhesive tape 1/4

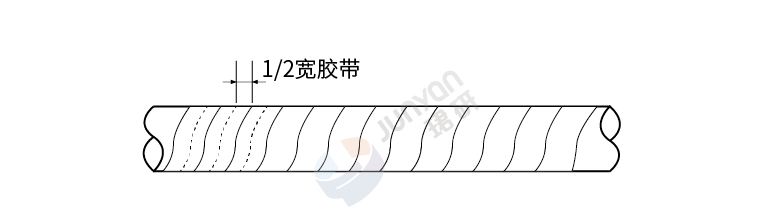

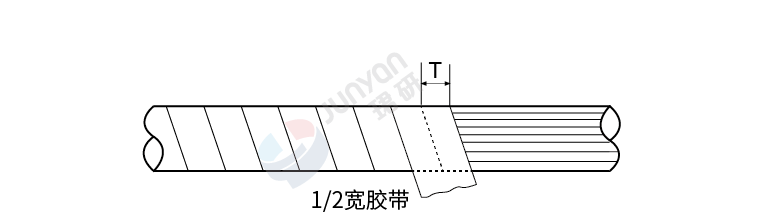

(4) Tightly wrapped adhesive tape 1/2

4. Tightly wrapped adhesive tape

(1) Specification of adhesive tape: use 0.13 * 19 * 20 adhesive tape

(2) Datum (indicated on drawing)

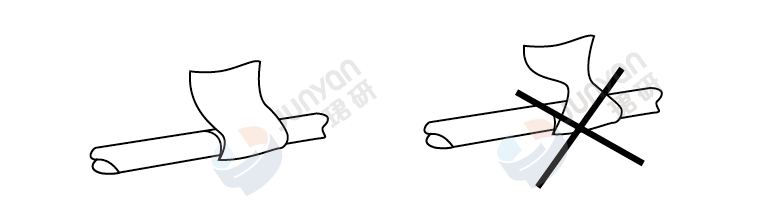

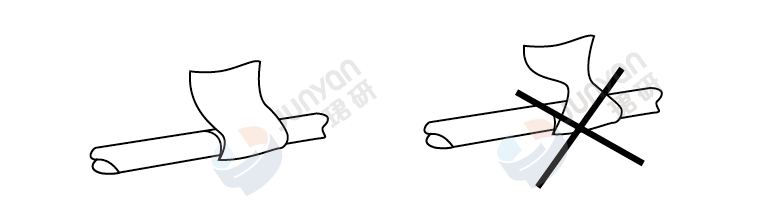

(3) Method: Do not stretch the tape around the wire

(4) Appearance

A. Even if it is bent to a right angle (where the tape is wrapped), the wires inside cannot be seen

B. Do not twist the tape winding part and peel off the end

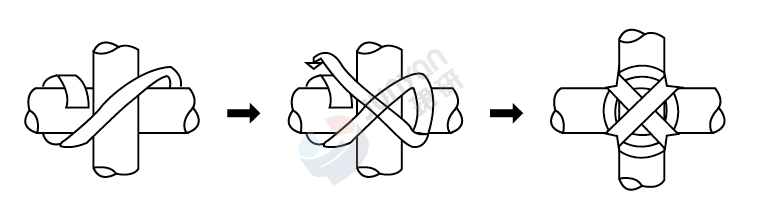

5. Branch tape wrapping

(1) Specification of adhesive tape: use 0.13 * 19 * 20 adhesive tape

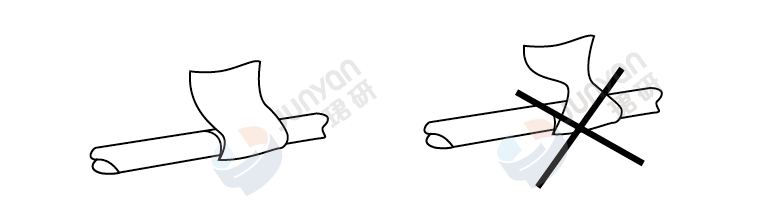

(2) Benchmark: stick the two sides of the cross bifurcation (inside and outside) to fix the wire and wrap it for more than two turns

(3) Winding method: do not stretch the tape, and wrap it on the wire carefully.

(4) Appearance

The winding part of the branch adhesive tape shall not be twisted, the end shall be peeled, and the wires shall not be visible after the adhesive tape is wrapped

。

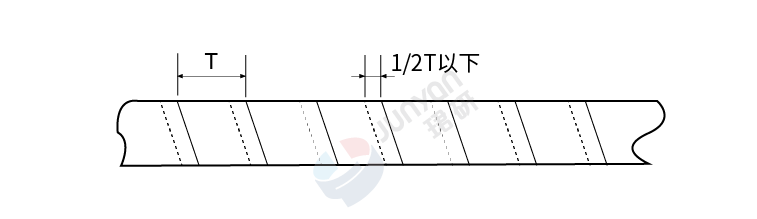

6. Loosely wound adhesive tape

(1) Specifications of adhesive tape

10mm(w)→≤ φ 7 (outside diameter of harness)

19mm(w)→≤ φ Above 7- φ 25 (outside diameter of harness)

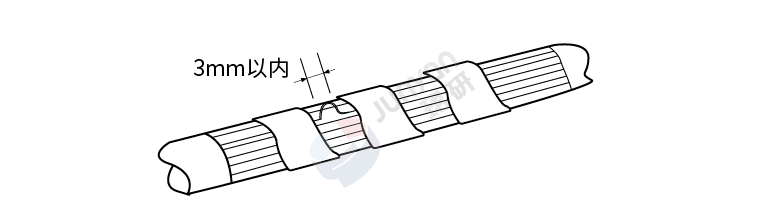

(2) Benchmark: the size of the adhesive tape room is equivalent to the width of the adhesive tape, and the wires can be seen.

When the tape wrapping space is less than 50 mm short or the number of wires is less than 5, when loosely wrapping the tape, if the overlap between the tape and the tape is less than 1/2, it is considered as loosely wrapping.

(3) Winding method: do not stretch the tape, and wrap it on the wire carefully.

(4) Appearance

A. After loosely wrapping the tape, do not twist the tape and peel the end.

B. There shall be no wire protrusion that may affect the appearance of the product. (If the wire protrudes within 3mm, it is qualified)

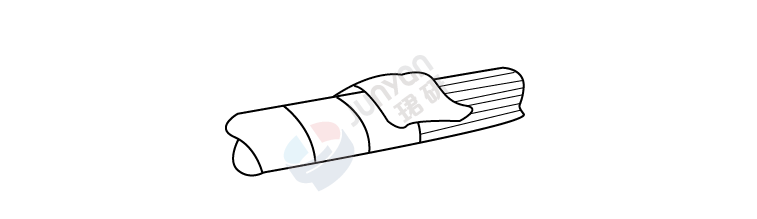

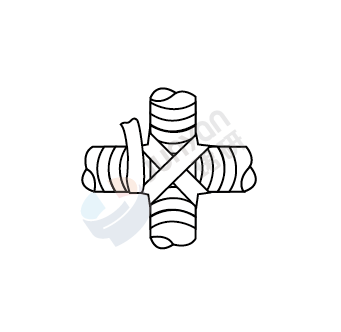

7. Wrap adhesive tape on the multi wire crimping part

(1) Specification of adhesive tape: 0.13 * 19 * 20 adhesive tape shall be used.

(2) Winding method: